The first MEMS microphone was introduced in 1983 and in the following 36 years microphone technologies have evolved significantly giving designer’s a wider range of choices than ever. Technology wise, since 2014 MEMs microphones have surpassed condenser microphones as being the most popular choice for developers.

But which technology to choose?

Electrets (or ECM – Electret Condenser Microphone)

Electret types and inside an electret microphone, Image adapted from Northwestern University

Since their commercialisation in 1961 by Bell Labs the electret microphone has been the mainstay of audio designs until recently.

Electrets belong to the category of condenser microphones, i.e., microphones that use a capacitive element to convert electrical signals from sound waves. Electret microphones are undoubtedly adequate in many applications; nevertheless, it’s also good to be aware that designers have another option: MEMS (or MicroElectrical-Mechanical Systems).

Electret advantages

The electrets key advantage has always been cost, the microphone itself can be very low cost but it does require an A to D converter in all but the most simple analogue only systems and this increases the overall system implementation cost.

Electrets also come in all sizes, except very small, and they are typically cylindrical. Because of their construction it is possible to buy them with solder pad, pin, surface mount and wire lead, so ECMs offer a wider range of mounting options.

MEMS microphones

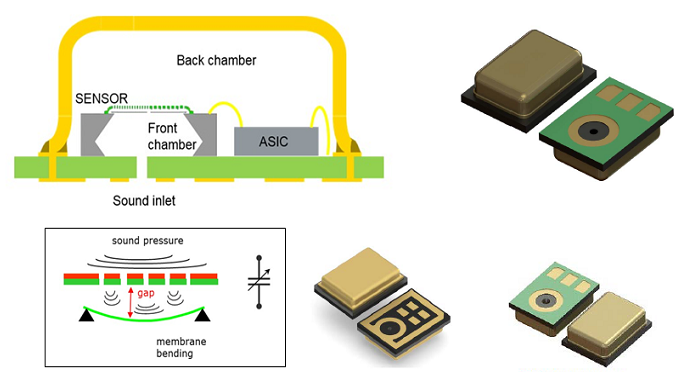

Knowles MEMS microphone die and typical MEMs construction. Image source: Chipworks

The MEMS microphone is also a category of condenser microphones. A pressure-sensitive diaphragm is etched directly into a silicon wafer by MEMS processing techniques, and is usually accompanied with integrated preamplifier. Most MEMS microphones are variants of the condenser microphone design but more recently ones based on piezo materials are starting to be offered.

MEMs microphones fall in to two categories, analogue and digital, each referring to the type of output signal.

The following applies to both analogue and digital designs but digital solutions also have some further benefits.

MEMs advantages

MEMS microphones can be reflow soldered, while ECMs cannot.

The charge on an ECMs diaphragm cannot withstand the high temperatures of a reflow soldering process, so they often must be hand-soldered to a board. MEMS microphones, however, can be assembled on the same reflow soldering process as other ICs on a PCB. This gives a potential cost saving as hand assembly may require an extra process step.

MEMS microphones have a higher “performance density” than ECMs. They are much smaller!

What this means is that a MEMS microphone will have much better noise performance than an ECM in an equivalent package size (volume). There are ECMs that match the low noise performance of MEMS microphones, but they are typically in a much larger package. For example, a typical MEMs microphone with a 65 dB SNR is offered a 2.5 x 3.35 x 0.88 mm package (7.4 mm^3), while an ECM with similar performance may have a diameter of 9 mm and a 4 mm height, for a 254 mm^3 volume.

MEMS microphones have wider operating temperature ranges.

Being based on silicon or piezo materials MEMS microphones support far wider operating temperature ranges than electrets, -40 to +85’C is not uncommon whereas ECMs are more likely to be limited to -20 to +70’C. This allows MEMs solutions to be used in more demanding applications, especially those that may be used in outdoor environments.

MEMS microphones have less variation in sensitivity over temperature.

ECM do not have great temperature performance and sensitivity may drift as much as +/-4 dB over their operating temperature range, while a MEMS microphone’s sensitivity may only drift by 0.5 dB over the same range. This provides better matching in multi microphone systems as well as more consistent performance in singe microphone applications.

MEMS microphones have lower vibration sensitivity than ECMs.

The mass of a MEMS microphone’s diaphragm, being much smaller, is lower than that of an ECM; so it will have less response to vibrations in a system. This can give an advantage of at least 12 dB.

MEMS microphones have more uniform part-to-part frequency response than ECMs.

This means that a random selection of MEMS microphones of the same type will have nearly-identical responses, while many ECMs of the same type may have significant variation in their responses, especially at high and low frequencies. This can be a problem, especially in microphone arrays that are counting on each microphone element having identical responses.

Digital MEMs advantages

Digital MEMS microphones can support multiple power modes.

Where a MEMS microphone has multiple power modes, it is typically a low-power microphone intended for very low-power applications. Simply by changing the clock speed to the microphone changes its power mode. Typically a Low Power Mode (LPM) enables the microphone to be used in an Always On listening mode for keyword spotting and ambient sound analysis. In this mode, the microphone also consumes its lowest current while retaining high electro-acoustic performance.

Having multiple power modes allow MEMS devices to save power while also offer better performance. The ability to switch power modes means that the devices do not have to compromise between energy consumption and performance. Changing power modes is achieved by modifying the microphone’s clock speed. It should be noted that as the clock speed decreases, so the does the performance of the microphone but less energy is then used, allowing the microphone to save more power.

Digital MEMS microphones are more immune to RF interference.

The output from a Digital MEMS microphone is, well, digital. It has two states and these are rail to rail signals independent of the level of the incoming audio, so any noise that is coupled to these signals (from other PCB tracking, RF interference, etc.) is insignificant by comparison and so has no effect on performance. In comparison the analogue signals from a microphone, of any type, can be very low at low sound levels and so adversely effected even by a small amount of coupling.

This lack of coupling also allows the microphones to be placed far from the rest of the system without any performance drop reduction giving the designer more flexibility in the physical format of the PCB

Digital MEMS microphones are easier to interface with.

Both Electret and Analogue MEMS require a dedicated codec device containing an analogue to digital converter. In comparison Digital MEMS microphones do not need a converter and so can interfaces directly to any digital input on a microcontroller, DSP or dedicated digital codec.

Question. Is a digital MEMS microphone based solution more expensive?

It depends on the application requirements, it is always possible to use the lowest cost components but this always is a trade-off between cost and performance.

Answer #1. Cost is not just the price of a single component, all the system requirements should be considered as well as the benefits of digital MEMS microphones show earlier. The size and robustness of MEMS solutions cannot be matched by ECMs.

Answer #2. If looking at cost alone, a cost analysis should always look at the whole audio chain from sound in to processed digital audio out, as a low cost microphone may not necessarily give the lowest cost solution.

The simpler analogue microphone requires a more complex codec, so more silicon area in a more expensive process (mixed signal devices are rarely on very small geometry processes), more testing and more cost.

In comparison the digital microphone requires a far simpler codec that can be realised as an all-digital circuit, taking advantages of smaller geometries. Such a codec is the CMX655D from CML Microcircuits Ltd, which supports two digital microphone channels, provides programmable filtering and other digital features and also integrates a 1 Watt Class D speaker amplifier.

The cost of Digital MEMS microphones continues to fall as they become the dominant type in all high volume applications. The economies of scale will mean that the current 20% difference between analogue and digital designs will close and the current 20% difference is already similar to the additional cost having the ADC integrated in the codec.

Summary

MEMS microphones can be considered a mature technology but the latest digital implementations now offer more benefits than even and can be integrated into designs easily and at low cost as more digital input codecs become available in the market.